Understanding Marine Engine Repair and Overhaul

Marine engine repair and overhaul are essential services for maintaining the performance, safety, and longevity of boats, yachts, and commercial vessels. Marine engines endure unique conditions, including exposure to saltwater, varying temperatures, and heavy usage, which can lead to wear and tear over time. Regular maintenance is important, but sometimes repairs or full overhauls are necessary to address mechanical issues, prevent breakdowns, and ensure reliable operation on the water.

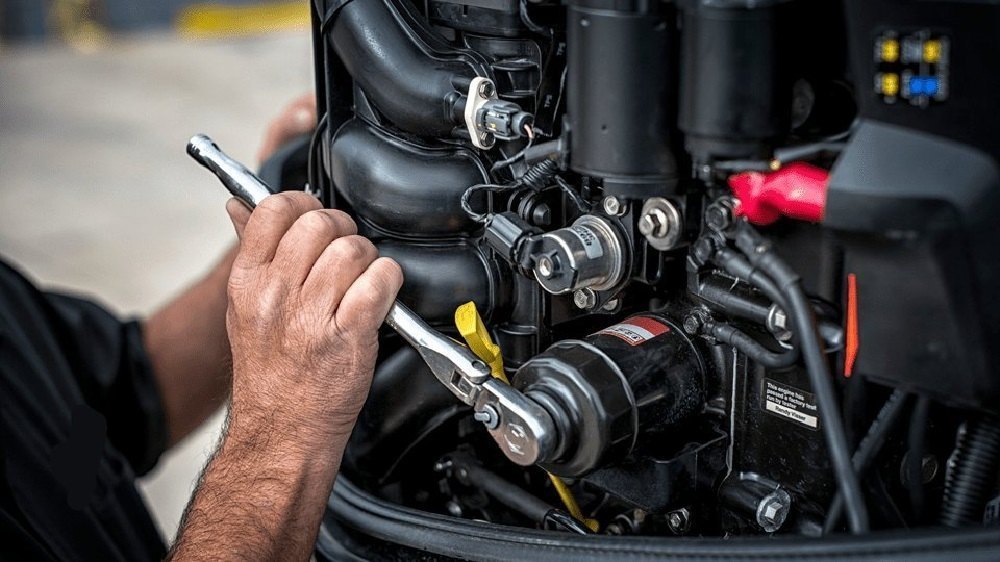

Repairing or overhauling a marine engine requires specialized knowledge and tools. Technicians trained in marine systems understand the complexities of engine components, fuel systems, cooling systems, and electronic controls. Their expertise ensures that repairs are done efficiently and correctly, reducing the likelihood of repeated problems or additional costs in the future. Understanding the process helps boat owners anticipate expenses and make informed decisions about servicing their vessels.

Factors That Affect Marine Engine Repair Costs

Several factors influence the cost of marine engine repair and overhaul. The type and size of the engine, whether it is inboard or outboard, diesel or gasoline, can significantly impact pricing. Larger or more complex engines typically require more labor and specialized parts, which increases overall costs. Similarly, high-performance or older engines may have limited availability of parts, making repairs more expensive.

The scope of the repair also affects pricing. Minor repairs, such as replacing gaskets, spark plugs, or filters, may be relatively inexpensive. Major repairs, including addressing cooling system failures, fuel injection issues, or internal engine damage, can be considerably higher. A full engine overhaul, which involves disassembling the engine, replacing worn components, and reassembling it to factory specifications, represents a significant investment but can extend the engine’s life by many years.

Labor rates vary based on the expertise of the technician and the complexity of the work. Experienced marine mechanics with specialized training often charge higher rates, but their skill can prevent costly mistakes and ensure long-term reliability. Geographic location may also play a role, as service rates differ between coastal areas, inland marinas, and commercial ports.

Additional Costs to Consider

Beyond parts and labor, boat owners should account for additional costs associated with marine engine repair and overhaul. Diagnostic services, towing, or hauling the vessel for repair can add to the total expense. In some cases, specialized testing equipment is required to identify hidden issues, which can also affect pricing.

Replacement parts for marine engines may include OEM (original equipment manufacturer) components or aftermarket alternatives. While OEM parts typically cost more, they often provide higher reliability and longer life, making them a worthwhile investment for critical systems. Aftermarket parts may be less expensive but require careful evaluation to ensure compatibility and durability.

Seasonal considerations can also influence costs. During peak boating seasons, repair shops may have higher demand, leading to longer wait times or premium charges. Planning maintenance and repairs during off-peak periods can help manage expenses while keeping the engine in optimal condition.

Strategies to Manage Marine Engine Repair Costs

Proactive maintenance is the most effective way to manage marine engine repair costs. Regular inspections, fluid changes, and timely replacement of worn components reduce the likelihood of major repairs and extend engine life. Keeping detailed maintenance records also helps technicians quickly identify potential issues, which can save time and labor costs during service.

Obtaining multiple quotes from reputable marine engine repair providers allows boat owners to compare prices, services, and warranties. While cost is important, it is equally crucial to choose a service provider with proven experience and a track record of quality workmanship. Cutting corners on repairs may lead to higher expenses down the line due to repeat issues or poor-quality parts.

Investing in high-quality replacement parts and materials during an overhaul can result in long-term savings. Choosing durable components and ensuring proper installation reduces the risk of frequent breakdowns and keeps the engine running efficiently. Some boat owners also consider service contracts or maintenance plans that include discounted repairs and scheduled inspections, which provide cost predictability and peace of mind.

Planning for Long-Term Value

Marine engine repair and overhaul should be approached as an investment in the vessel’s safety, performance, and resale value. A well-maintained engine enhances the boat’s reliability and operational efficiency, making it more attractive to potential buyers if the owner decides to sell. Understanding the costs, planning for preventive maintenance, and working with skilled professionals helps boat owners maximize the return on their investment.

In addition, strategic planning allows boat owners to budget for future repairs and overhauls. By anticipating the potential lifespan of engine components and scheduling proactive maintenance, owners can avoid unexpected financial strain while maintaining peak performance. This long-term approach ensures that the vessel remains safe, reliable, and enjoyable for years to come.