Molded pulp is becoming recognized as an environmental leader in the constantly changing field of sustainable packaging options. As the world grapples with the consequences of plastic pollution and seeks alternatives to traditional packaging materials, molded pulp has risen to prominence for its eco-friendly attributes and versatile applications. At the heart of this sustainable revolution are molded pulp suppliers, whose pivotal role extends beyond mere production to shaping a greener future for packaging industries worldwide.

Molded Pulp: An Eco-Friendly Marvel

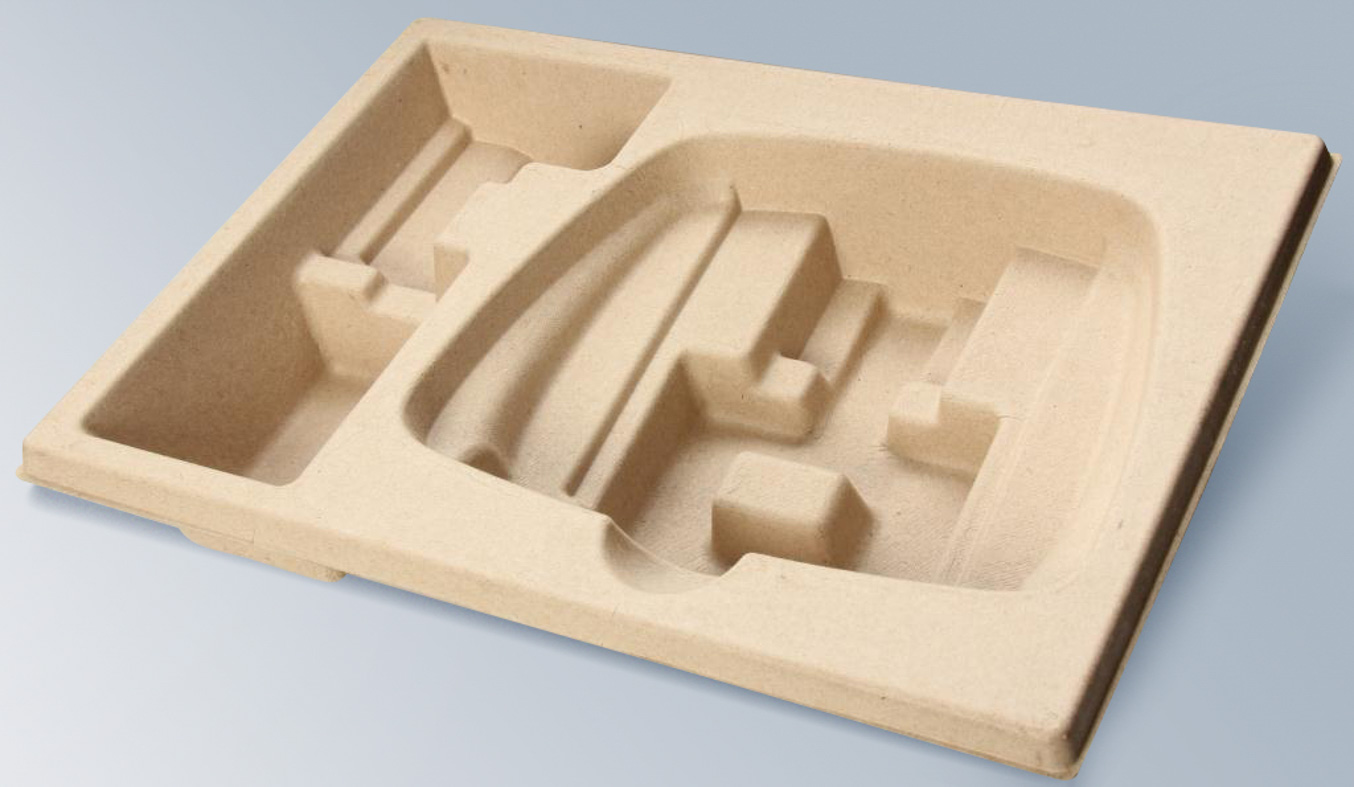

The molded pulp, often derived from recycled paper and cardboard, represents a compelling alternative to plastic and styrofoam packaging. Its production process involves transforming natural fibers into sturdy, customizable forms through molding techniques. This approach not only utilizes renewable resources but also minimizes waste by repurposing materials that would otherwise contribute to landfill accumulation.

The versatility of molded pulp is another hallmark of its appeal. It is appropriate for a wide range of packaging demands, from fragile electronics to food products and beyond, because suppliers may mold it into different shapes and sizes. It ensures product safety and environmental responsibility by having cushioning and protecting capabilities that rival that of standard packaging materials while products are in transit.

The Environmental Imperative: Why Molded Pulp Matters

The urgency of addressing environmental concerns has propelled molded pulp into the spotlight. Masticated pulp products, in contrast to plastics, can biodegrade and compost under the correct circumstances, lasting for generations in the environment. This characteristic significantly reduces their environmental footprint, offering a sustainable end-of-life solution that aligns with circular economy principles.

Moreover, the production of molded pulp generates lower carbon emissions compared to conventional packaging materials. By utilizing recycled fibers and renewable resources, suppliers contribute to mitigating greenhouse gas emissions and promoting resource efficiency—a crucial step in combating climate change.

Driving Sustainable Practices: The Role Of Molded Pulp Suppliers

Molded pulp suppliers play a pivotal role in advancing sustainable practices within the packaging industry. Through innovation and collaboration, they spearhead efforts to integrate eco-friendly solutions into mainstream packaging strategies. Here’s how:

- Material Sourcing And Recycling Initiatives: Suppliers source raw materials from responsibly managed forests and prioritize the use of recycled paper and cardboard. By supporting recycling initiatives, they reduce demand for virgin materials and encourage a closed-loop system that conserves natural resources.

- Customization And Design Excellence: The adaptability of molded pulp allows suppliers to tailor packaging solutions to specific customer requirements. Whether it’s intricate designs for electronics or protective trays for food items, customization ensures optimal functionality without compromising sustainability.

- Certifications And Compliance: Leading molded pulp suppliers adhere to stringent environmental standards and certifications. These endorsements underscore their commitment to responsible sourcing and manufacturing practices.

- Research And Development: Continuous innovation drives the evolution of molded pulp technologies. Suppliers invest in research and development to enhance product performance, explore new applications, and reduce environmental impacts further. This ongoing pursuit of excellence fosters a culture of sustainability within the industry.

Market Adoption And Future Outlook

The adoption of molded pulp packaging continues to gain momentum across diverse sectors, including electronics, consumer goods, and food service industries. Businesses recognize the value of sustainable packaging in enhancing brand reputation, meeting regulatory requirements, and appealing to eco-conscious consumers.

Looking ahead, the future of molded pulp suppliers appears promising. Advances in technology and increasing consumer awareness are poised to drive demand for eco-friendly packaging solutions. As suppliers expand their capabilities and collaborate with global partners, the scalability of molded pulp production is expected to grow, offering scalable solutions that meet the evolving needs of a sustainable economy.

Conclusion

In conclusion, molded pulp suppliers play an indispensable role in advancing eco-friendly packaging solutions. Their dedication to sustainability, creativity, and ethical business practices highlights how moldable pulp may be a game-changer in lowering environmental effects and fostering a circular economy. By choosing molded pulp, businesses not only embrace a viable alternative to traditional packaging materials but also contribute to a more sustainable future for generations to come.